Description

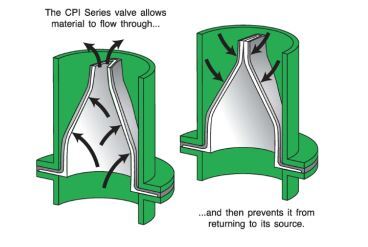

The In-Line Flanged Series Rubber Duckbill Check Valve – Series CPI is designed to be efficient, quiet and tough. It requires no external power sources, thereby reducing operating costs. The valve’s simple design means there are no moving mechanical parts to break down or jam reducing maintenance costs.

CPI Valves easily handle corrosive or abrasive materials such as raw sewage, sludges or slurries. Their flexible design allows solids to pass through unhindered and can even surround solids trapped in the valve.

Series CPI In-LineRubber Duckbill Check Valves are versatile and can be installed either horizontally or vertically. Drilling is available in all flange standards.

The series CPI/IN is also available as an insert type check valve. An internal clamp is used to fasten the check valve to the inside of an existing pipe.

The heart of the Elasto-Valve Series CPI Backflow Preventer is a fabric reinforced rubber “duckbill” sleeve manufactured with top quality materials. This flexible sleeve provides maximum flow with a minimum pressure drop across the valve at all times.

Unlike conventional check valves – which require frequent maintenance to replace worn seats, hinge pins, balls or flappers – there is little or no maintenance with CPI Valves.

Available in a variety of styles and reinforced elastomers, the Elasto-Valve Series CPI Backflow Preventer can be adapted to almost any application.